SOLUTIONS

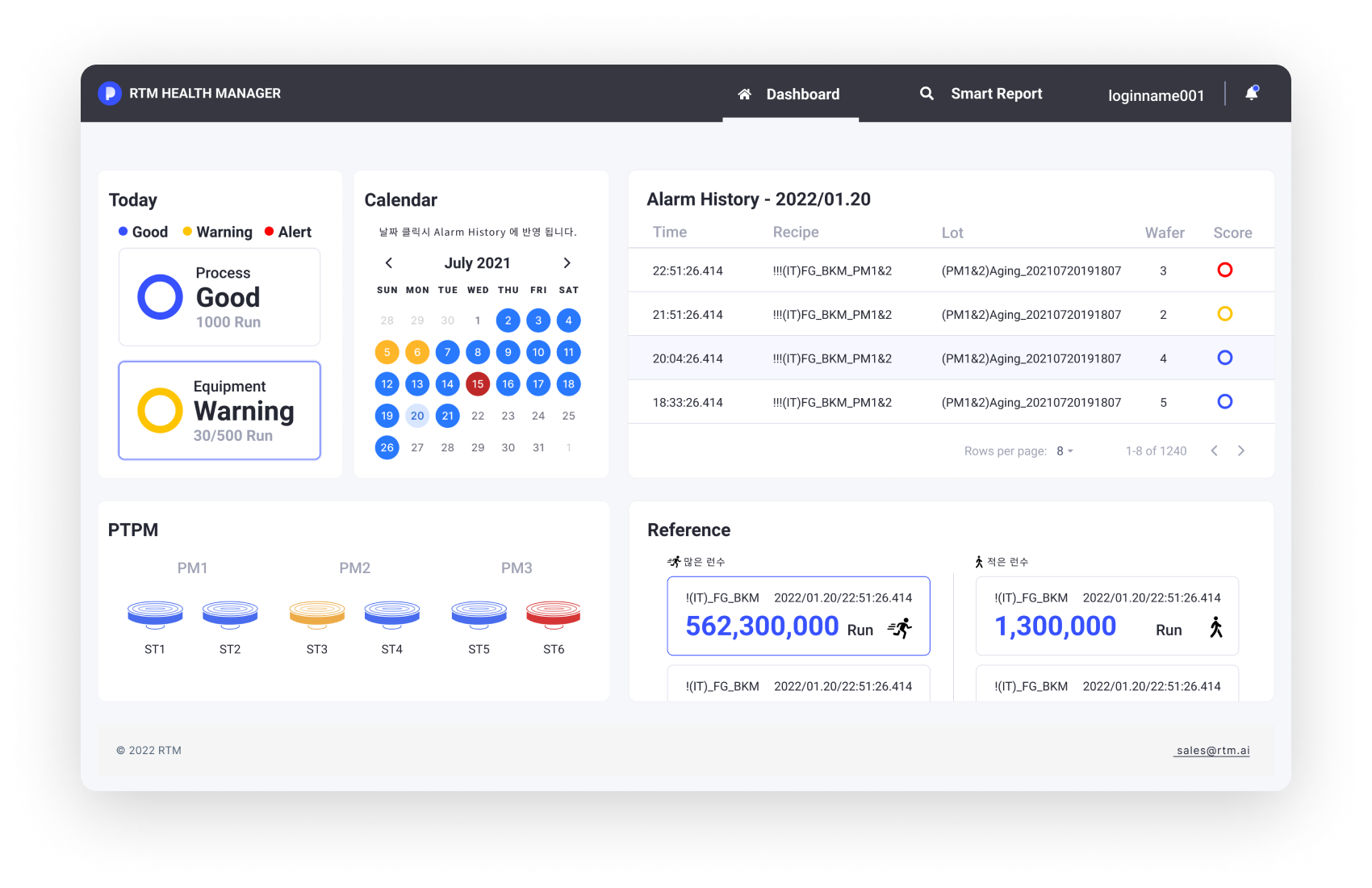

Explainable AI (XAI) solution collecting and analyzing high volume equipment sensor data

Explainable AI (XAI) solution collecting and analyzing high volume equipment sensor data

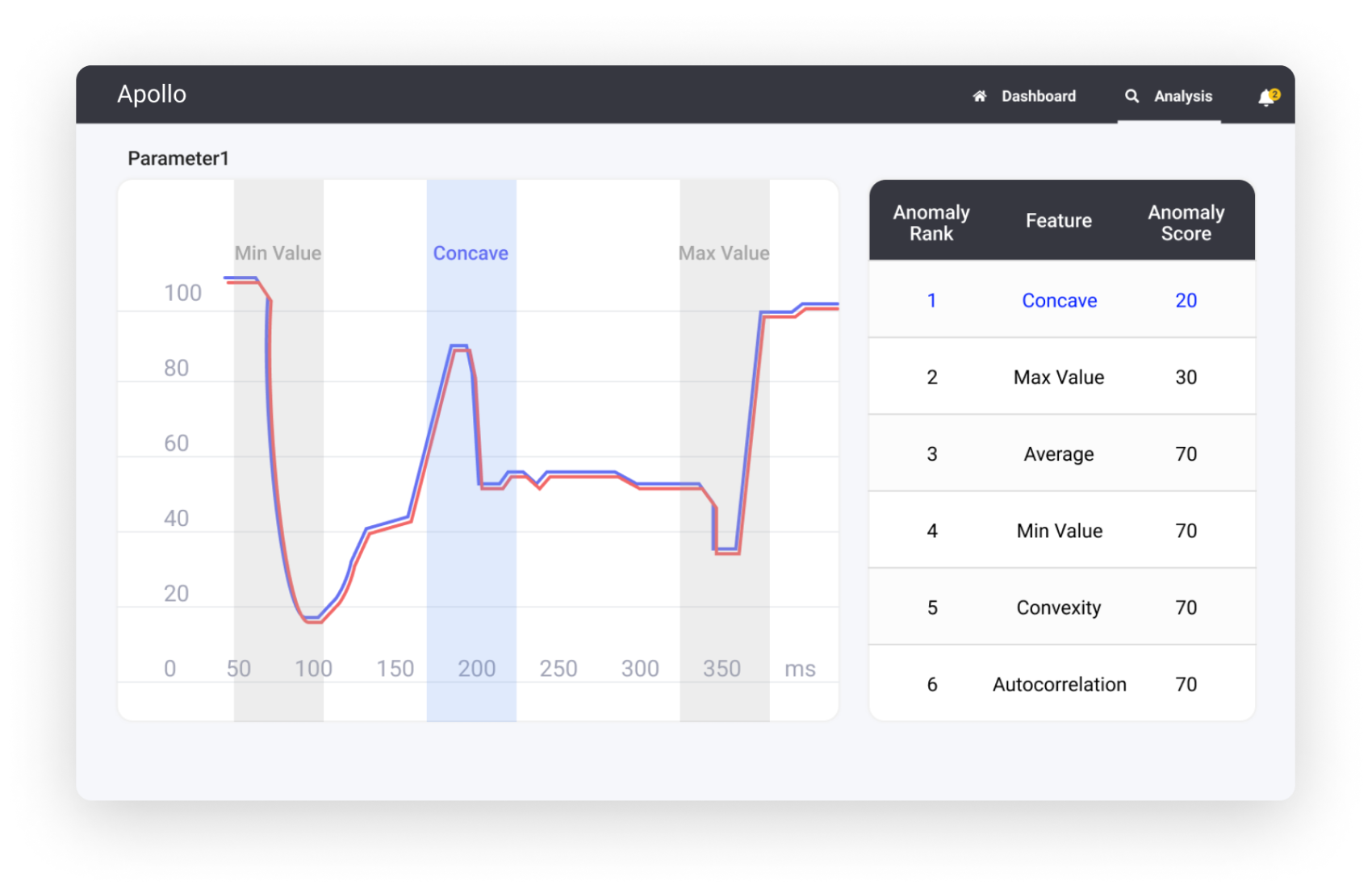

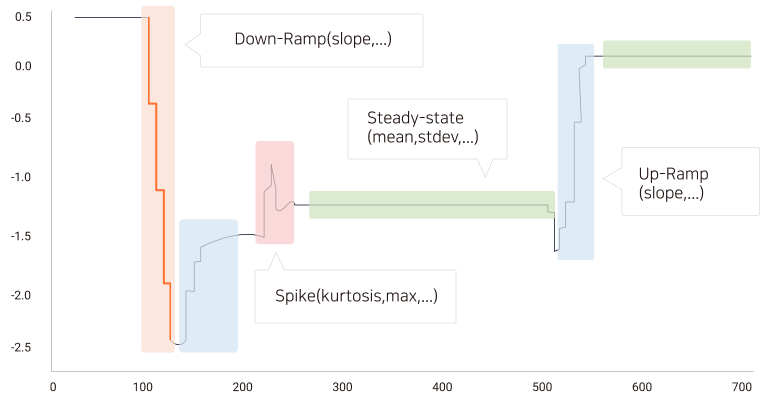

Identify process anomalies through observations of time series data patterns

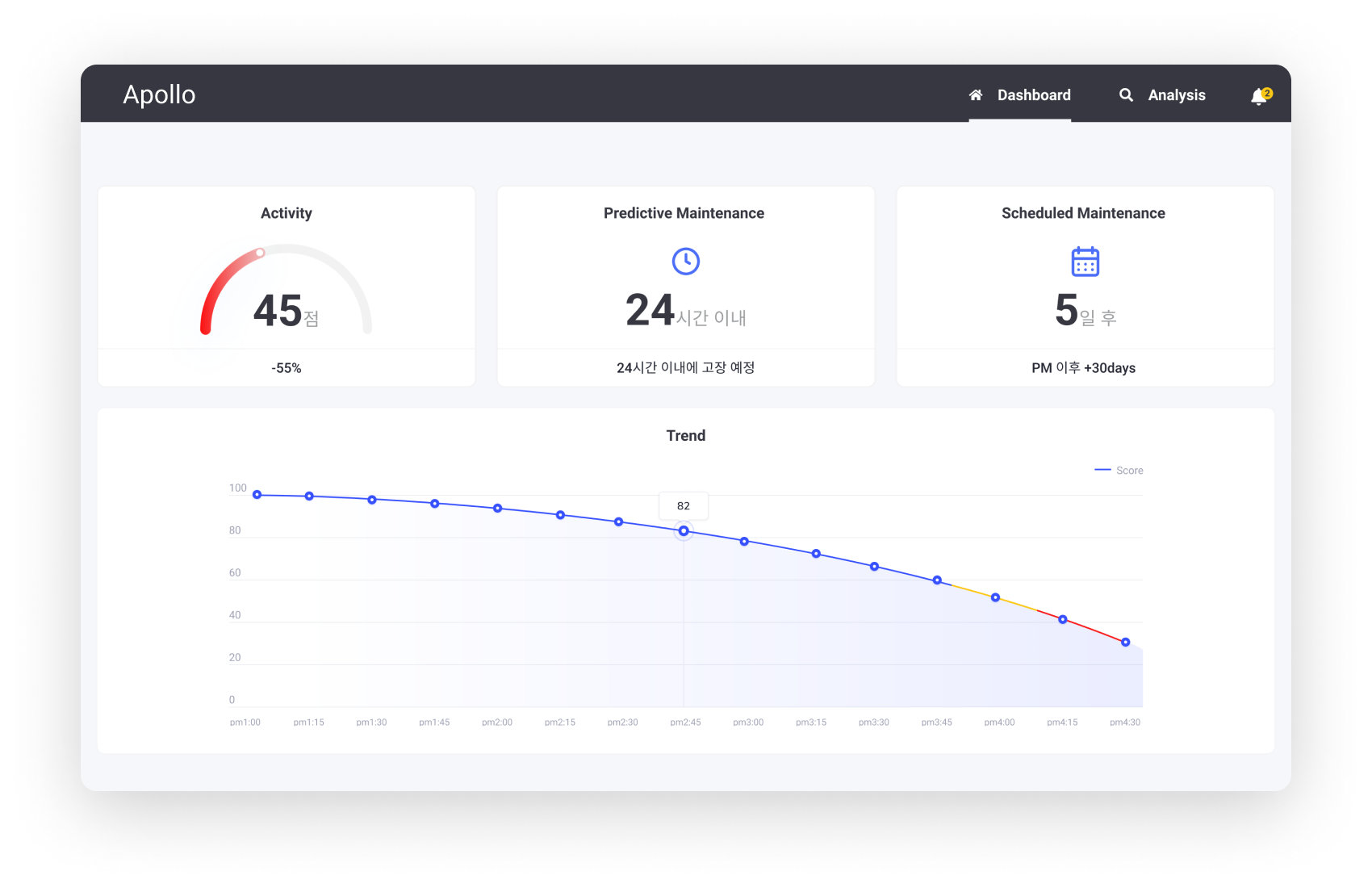

Minimize manufacturing downtime by predicting remaining useful life(RUL) of your equipment

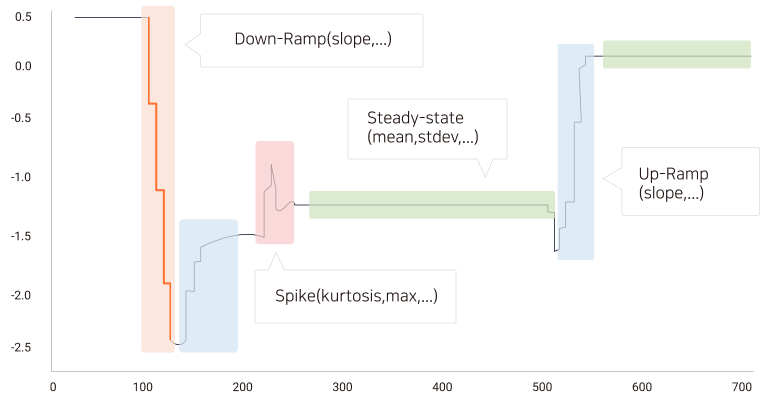

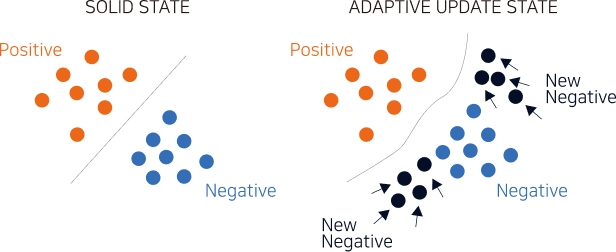

Maintain an optimal manufacturing operation with real-time AI model adaption technology

RTM creates a higher standard of diagnositic technology with explainable AI modeling

RTM creates a higher standard of diagnositic technology with explainable AI modeling

RTM creates a higher standard of diagnositic technology with explainable AI modeling

RTM allows faster response to process anomalies with advancing pattern detection technology

RTM allows faster response to process anomalies with advancing pattern detection technology

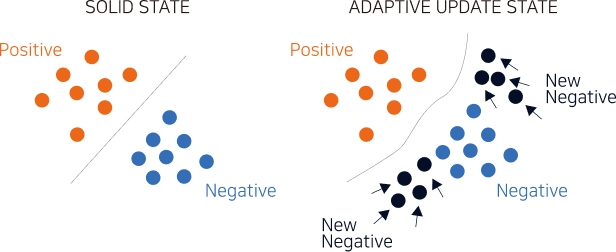

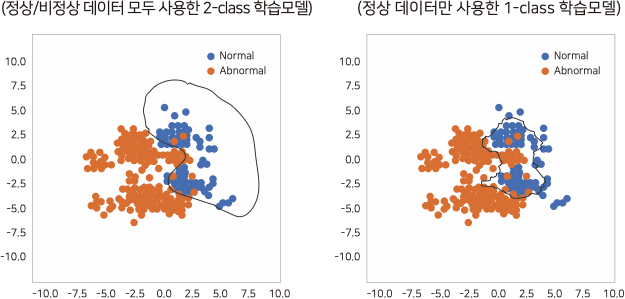

RTM technology enables users with limited data to create a quality AI model.

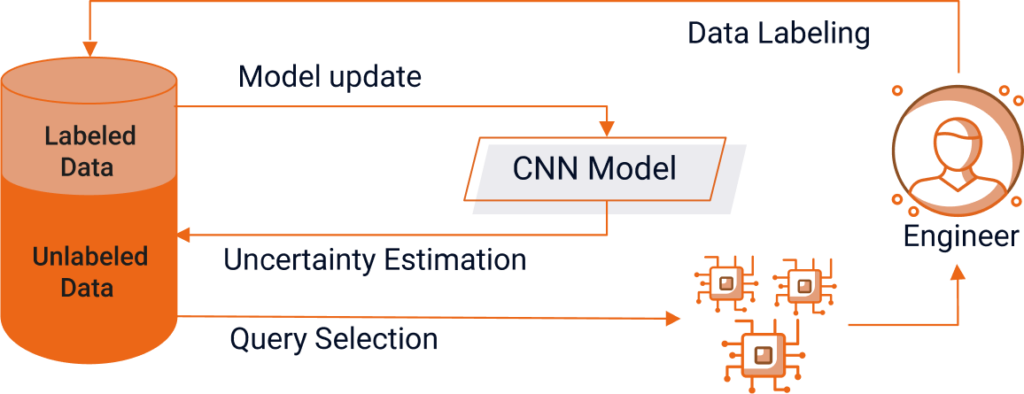

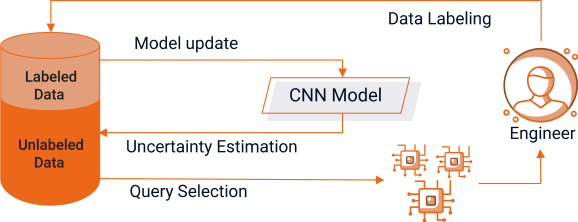

RTM develops reliable and accurate algorithms to maximize your operation efficiency

RTM allows faster response to process anomolies with advancing pattern detection technology

RTM technology enables users with limited data to create a quality AI model.

RTM develops reliable and accurate algorithms to maximize your operation efficiency

Life expectancy, Anomaly Detection

Application : Virtual metrology (OES) / Process

anomaly detection /

Warpage/ Leak detection/ Plasma source

Anomaly Detection

Application : Plasma welding

Life expectancy, Anomaly Detection

Application : Vacuum pump assembly

Life expectancy, Anomaly Detection

Application : Virtual metrology (OES) / Process

anomaly detection /

Warpage/ Leak detection/ Plasma source

Anomaly Detection

Application : Plasma welding

Life expectancy, Anomaly Detection

Application : Vacuum pump assembly

Research Lab

서울시 강남구 역삼로3길 11 광성빌딩 본관 10층, 11층

Headquarter

서울시 강남구 역삼로3길 11 광성빌딩 본관 7층

sales@rtm.ai

Fax

070.7543.6780

Tel

02.2088.6780

Research Lab

10F Kwangsung Bldg, 11, Yeoksam-ro 3-gil, Gangnam-gu, Seoul, Republic of Korea

Headquarter

7F Kwangsung Bldg, 11, Yeoksam-ro 3-gil, Gangnam-gu, Seoul, Republic of Korea

Email

Tel

Fax

admin@rtm.ai

02.2088.6780

070.7543.6780