Solutions

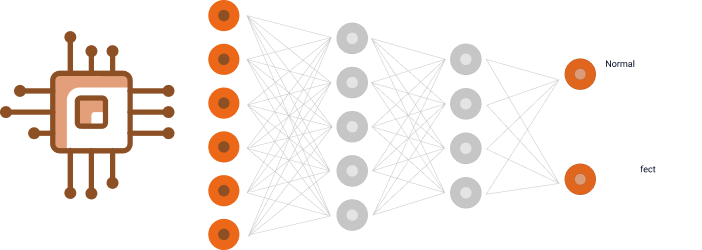

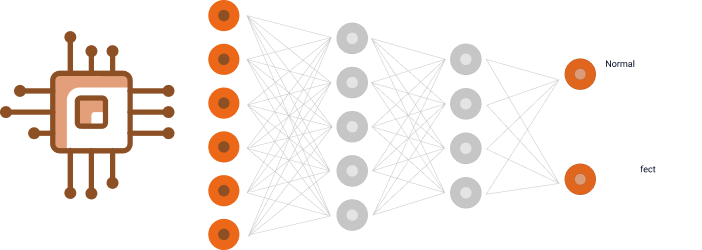

Deep learning-based vision solution maximizing your productivity beyond traditional vision inspection tools and methods

Deep learning-based vision solution maximizing your productivity beyond traditional vision inspection tools and methods

Classify newly discovered defects with AI models that learn various defect types in real-time

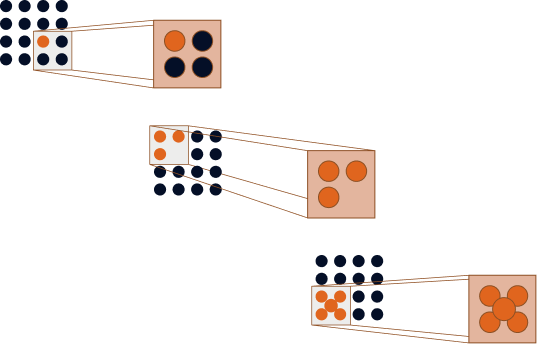

Detect and extract product abnormalities within region of interest for detailed analysis

Improve anomaly detection rate and accuracy with verified continual learning algorithms

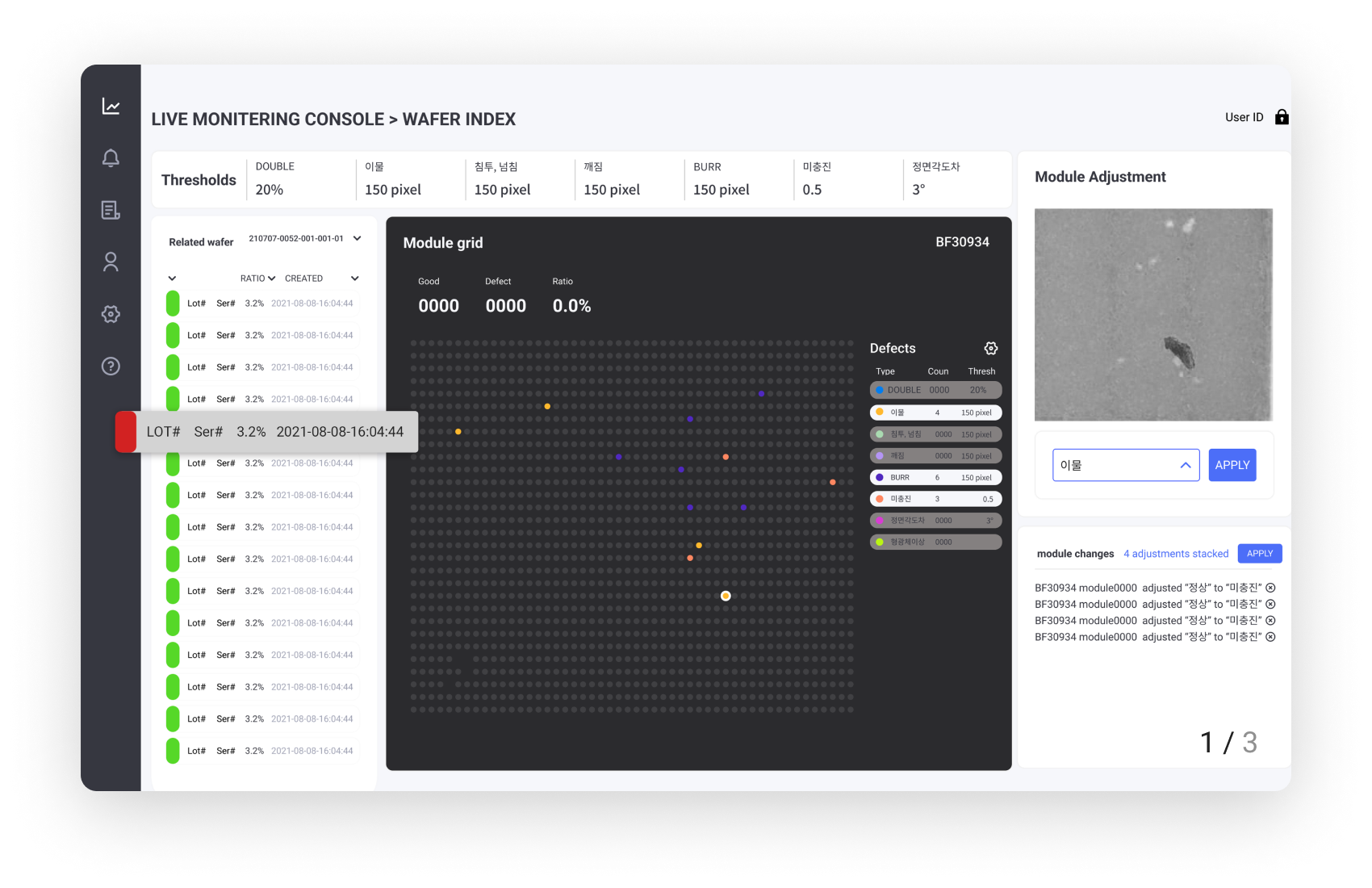

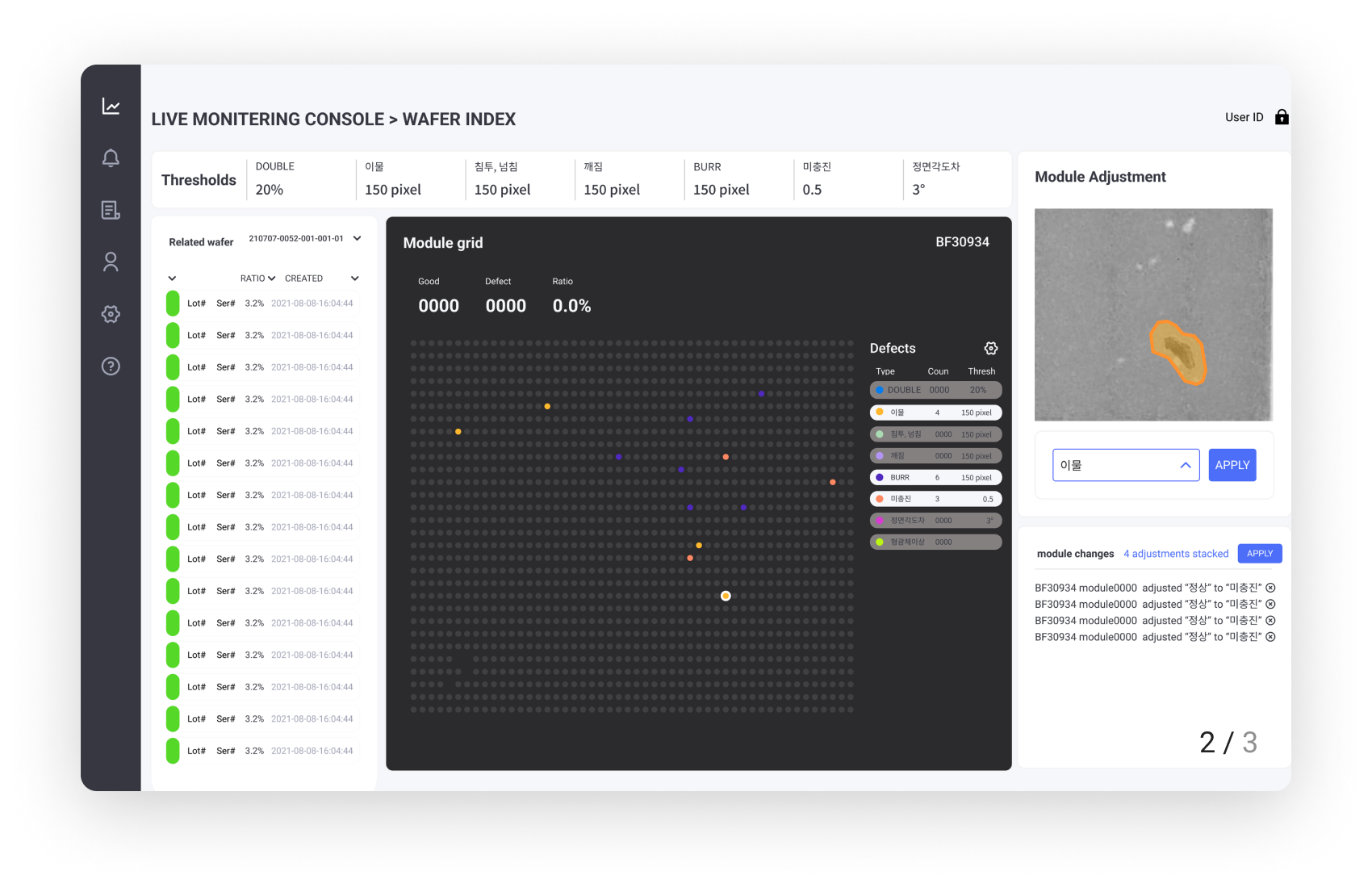

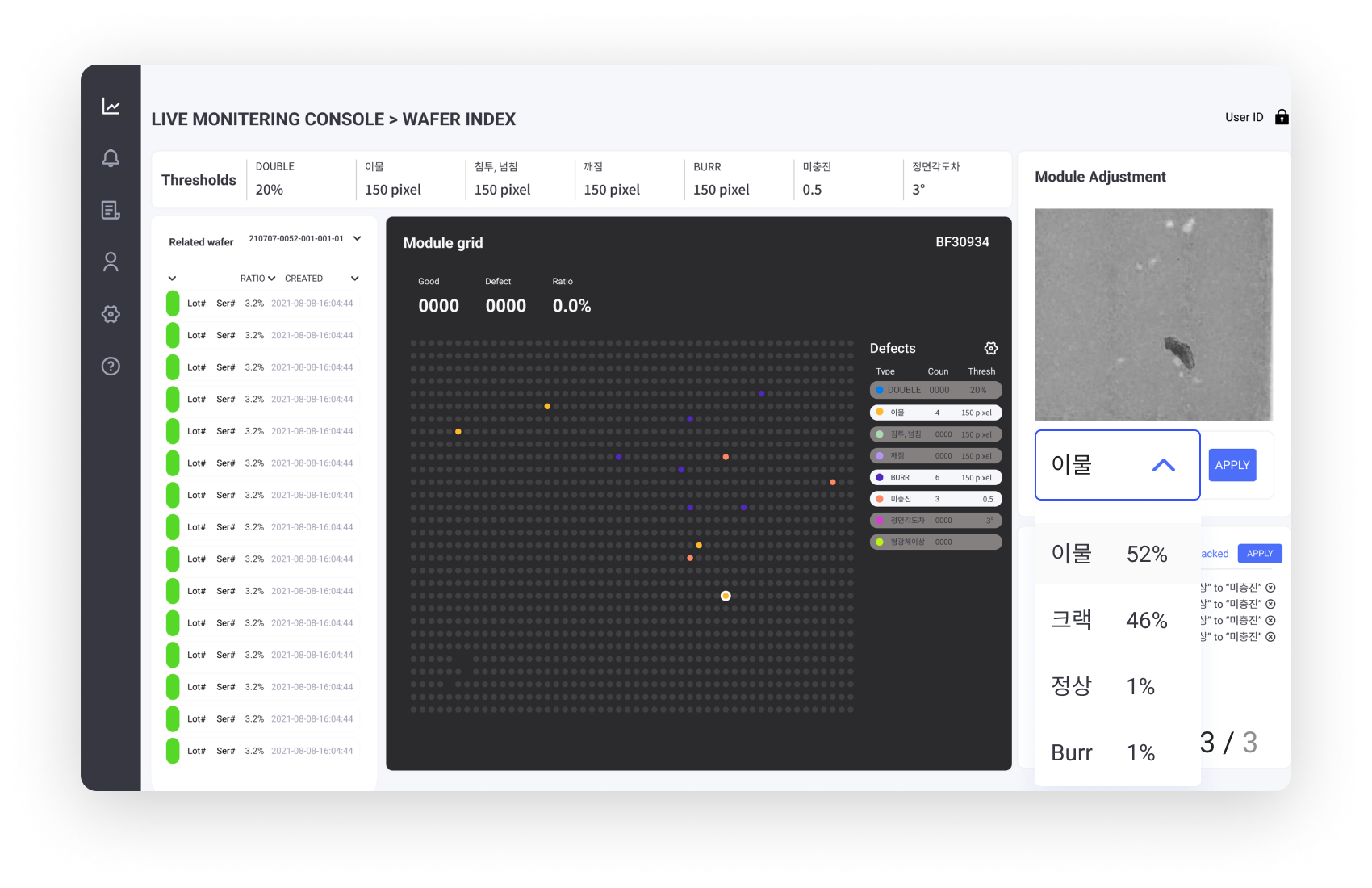

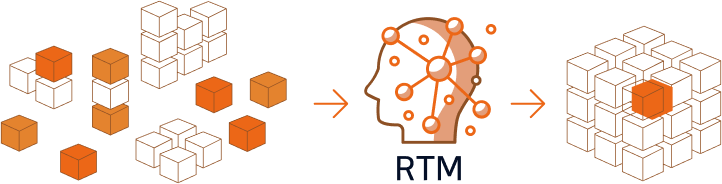

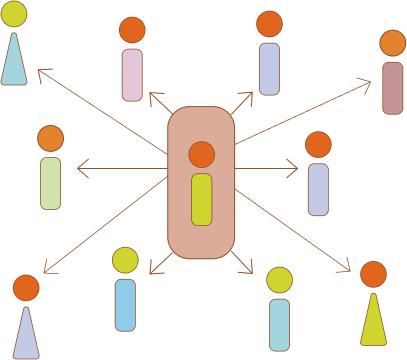

RTM delivers easy-to-understand data for all users through advanced image processing technology

RTM adjusts target regions based on user image requirements to maximize detection accuracy

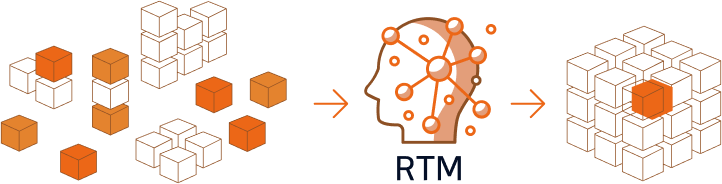

RTM technology enables users with limited data to create a quality AI model.

RTM detects and specifies location of defect for detailed analysis

RTM delivers easy-to-understand data for all users through advanced image processing technology

RTM adjusts target regions based on user image requirements to maximize detection accuracy

RTM technology enables users with limited data to create a quality AI model.

RTM detects and specifies location of defect for detailed analysis

Classification

Application : LED void, LED AOI

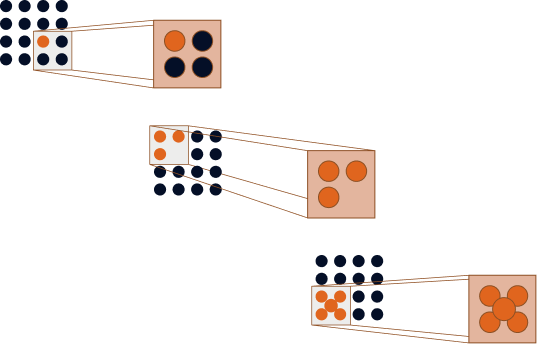

Classification, Segmentation

Application : Pellicle

Classification, Segmentation

Application : Heater block

Classification

Application : LED void, LED AOI

Classification, Segmentation

Application : Pellicle

Classification, Segmentation

Application : Heater block

Research Lab

서울시 강남구 역삼로3길 11 광성빌딩 본관 10층, 11층

Headquarter

서울시 강남구 역삼로3길 11 광성빌딩 본관 7층

sales@rtm.ai

Fax

070.7543.6780

Tel

02.2088.6780

Research Lab

10F Kwangsung Bldg, 11, Yeoksam-ro 3-gil, Gangnam-gu, Seoul, Republic of Korea

Headquarter

7F Kwangsung Bldg, 11, Yeoksam-ro 3-gil, Gangnam-gu, Seoul, Republic of Korea

Email

Tel

Fax

admin@rtm.ai

02.2088.6780

070.7543.6780